What Determines Motor Life?

Sure! Here's the rewritten content in English:

---

Understanding how to use a product correctly can significantly impact its performance and lifespan. For instance, proper care of cast iron pans can extend their longevity. Similarly, electric motors benefit greatly from understanding the factors influencing their lifespan, which can help optimize performance and reduce costs over time.

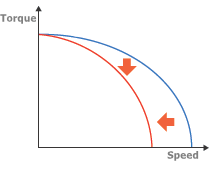

First, what defines the end of a motor's life? Typically, it means when the motor no longer meets the specifications outlined in its documentation. While the motor may still operate, it won’t function as intended if it can't achieve the specified speed, torque, or accuracy. When a motor can't perform its designated tasks, it essentially becomes unusable to us.

**Key Factors Affecting Motor Lifespan**

The lifespan of any product usually depends on the first component to fail. In the case of geared motors, the three most common components prone to failure are the bearings, gears, and circuitry like drivers and controllers.

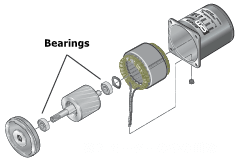

**Bearings**

Bearing failure can halt a motor’s operation entirely. Bearings act as crucial components by reducing friction between moving parts and supporting the shaft and rotor. Damage to bearings directly impacts the motor's ability to function.

Standard motor lifespans are often calculated based on bearing grease life, which is highly sensitive to temperature fluctuations. Exceeding the motor's specified load limits—whether radial or axial—can also shorten its life. Some advanced motors with long-lasting grease can operate for up to 10,000 hours.

**Gears**

Gears play a vital role in adjusting motor speed and increasing torque. They endure direct mechanical stress and can wear out over time, particularly under heavy or impact loads. Once gears degrade, the motor might still run but will produce noticeable noise and excessive backlash, failing to meet performance standards.

**Circuitry Components**

Drivers and controllers, which manage power delivery and logic commands for stepper and servo motors, are susceptible to failure due to overheating. The longevity of these circuits largely depends on the lifespan of their electrolytic capacitors, which are sensitive to high temperatures.

**How Temperature Affects Lifespan**

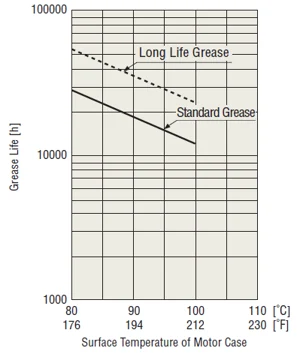

Heat plays a significant role in determining a motor's lifespan. Several factors contribute to motor degradation, including insulation breakdown, wear on moving parts, and bearing wear. Most motor lifespans are tied to bearing longevity, which in turn depends heavily on grease life, which is directly impacted by temperature. High temperatures can cut grease life in half, as can rolling fatigue.

Additionally, the life of electrolytic capacitors halves for every 10°C (18°F) increase in ambient temperature. Managing temperature effectively is essential for maximizing motor lifespan.

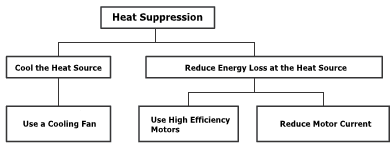

**Controlling Heat Rise**

There are two primary strategies to manage heat in motors: cooling the heat source and reducing heat generation. Cooling methods include using fans, improving heat radiation through larger metal plates, and enhancing heat dissipation. Lowering operating temperatures not only extends bearing grease life but also increases the motor’s duty cycle. In one application, I worked on, a water-cooled jacket was implemented to nearly double the stepper motor’s duty cycle.

Another effective method is minimizing energy losses at the motor. Energy loss typically manifests as heat, so reducing losses also decreases temperature. Using high-efficiency or continuous-duty motors can achieve this. For stepper and servo motors, reducing current flow lowers temperature since current is directly proportional to heat production. However, current also correlates with torque, so finding a balance between minimal temperature and adequate torque is key.

Thank you for reading! Please consider subscribing for more insights.

For further details on how temperature influences service life and rated life across different products, check out our technical reference section in the catalog for a deeper dive.

If you're interested in exploring cooling fans, high-efficiency motors, or strategies to minimize current usage, feel free to reach out to our technical support team. They’re always ready to assist with your specific needs.

---

I hope this version meets your requirements! Let me know if there’s anything else you'd like adjusted.

Metal Welding Parts,Surface,Treatment and Testing,Customization Size Figure

Changzhou Fuku Precision Machinery Co., Ltd. , https://www.fukuindustrial.com