Finned Tubes and their applications

Finned tubes are widely used in applications that require the transfer of heat from a hot fluid to a cooler one across the tube wall. The rate at which heat is transferred depends on several factors, including the temperature difference between the two fluids, the heat exchange between the fluids and the tube wall, and the surface area available for heat transfer.

Table of contents

- What is finned tube?

- Different types of finned tubes

- Why Finned Tubes are made of Aluminum?

- Finned tube heat exchanger working principle

- Low fin tubes dimension

- Uses Of Helical solid finned tubes

- Advantages of Using Fin and tube heat exchangers

- G Type Finned Tube Features

- Quality Control for Stainless steel finned tube

- Size Range Of G Type Fin Tube

- Classification of Finned tubes based on process and fin shape

- High fin tubes Vs Low fin tubes

- What can Cause Leakages in Low Fin Tubes?

- What Affects the Heat Transfer in a Low Fin Tube?

What is finned tube?

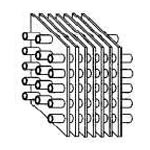

Finned tubes are elongated tubes with small fins attached to their outer surfaces, acting as efficient heat exchangers. These fins enhance the surface area, allowing more effective heat transfer between the inside and outside of the tube. They are commonly used in heat exchangers to facilitate heat exchange between thermally conductive fluids.

View different types of fin tubes for heat exchangers

The following table provides an overview of essential fin tube types used in heat exchangers. It helps you choose the most suitable type based on your specific application requirements and performance expectations.

Different types of finned tubes

| Fin Type | Icon | Tube Material | Fin Material | Fin Height | Fin Thickness | Tube Diameter |

|---|---|---|---|---|---|---|

| Plain Finned |  |

Carbon steel, stainless steel, copper, aluminum | Aluminum, copper, stainless steel | 6-25 mm | 0.2-0.6 mm | 12.7 mm (1/2") to 63.5 mm (2.5") |

| L-Finned |  |

Carbon steel, stainless steel, copper | Aluminum, copper, stainless steel | 6-19 mm | 0.3-0.5 mm | 15.9 mm (5/8") to 38.1 mm (1.5") |

| G-Finned |  |

Carbon steel, stainless steel, alloy steel | Aluminum, copper | 6-15 mm | 0.3-0.5 mm | 15.9 mm (5/8") to 50.8 mm (2") |

| Extruded Finned |  |

Aluminum, copper | Aluminum | 8-16 mm | 0.4-1.2 mm | 12.7 mm (1/2") to 31.8 mm (1.25") |

| U-Tube Finned |  |

Carbon steel, stainless steel, alloy steel | Aluminum, copper, stainless steel | 6-25 mm | 0.3-0.5 mm | 15.9 mm (5/8") to 38.1 mm (1.5") |

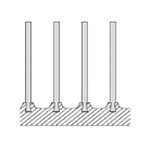

| Studded Finned |  |

Carbon steel, stainless steel, alloy steel | Carbon steel, alloy steel | 10-50 mm | 6-12 mm | 25.4 mm (1") to 114.3 mm (4.5") |

| Helical Finned |  |

Carbon steel, stainless steel, copper, aluminum | Aluminum, copper, stainless steel | 8-16 mm | 0.3-0.5 mm | 12.7 mm (1/2") to 76.2 mm (3") |

Refer sizes and uses of finned aluminum tubing

Finned aluminum tubing is commonly used in refrigeration systems, air conditioning units, and industrial processes where heating and cooling are required. Its high heat transfer capacity and durability make it a preferred choice over other types of heat exchangers.

Why Finned Tubes are made of Aluminum?

Aluminum finned tubes have a size range of 3/8" to 1 1/2".

Aluminum is widely used for manufacturing finned tubes due to its excellent properties:

- High thermal conductivity

- Lightweight

- Corrosion resistance

- Ductility and malleability

- Cost-effective

Finned tube heat exchanger working principle

Finned tube heat exchangers are primarily used to transfer heat from one fluid to another through the tubes. The fins increase the surface area, thereby enhancing the efficiency of heat transfer.

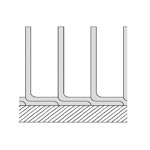

Low fin tube has a fin of about 1/16th in height

A low fin tube is a standard tube with a small fin, typically around 1/16th of an inch in height. The fin is embedded within the tube wall. These tubes are often used in liquid-to-liquid or liquid-to-gas applications, such as in coolers, chillers, and condensers.

Low fin tubes dimension

| Description | Size dimension |

|---|---|

| Tube Outside Diameter | Min. 12.7mm / Max. 31.75mm |

| Tube thickness (plain section) | Min. 1.245mm / Max. 3.404mm |

| Fin pitch | 19 – 26 – 27 – 28 – 30 – 36 fins per inch |

| Fin height | Max. 1,40mm |

| Tube length | Max. 25000mm |

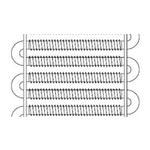

Welded Helical solid finned tubes widely used in petrochemical industry

These tubes offer resistance to corrosion, high pressure, and extreme temperatures, making them ideal for use in the petrochemical industry and industrial boilers. They are used to heat, cool, or recover heat from industrial exhaust gases.

Uses Of Helical solid finned tubes

- Petrochemical industries

- Natural gas processing

- Blast furnace and converter system

- Power generation

- Waste incinerators

- Air conditioning

- Compressor coolers

Advantages of Using Fin and tube heat exchangers

- Increases heat transfer rate

- Improves heat transfer coefficient

- Reduces equipment size

- Makes projects more cost-efficient

- Increases outside surface area

G Type Finned Tube Features

- High fin stability

- Superior heat transfer efficiency

- Ability to operate at elevated temperatures

- Excellent temperature resistance

- Exceptional thermal shock resistance

Quality Control for Stainless steel finned tube

- Chemical composition analysis

- Dimensional inspection

- Flatten test

- Non-destructive testing

- Hydrostatic test

- Mechanical property testing

- Expansion test

- Surface quality check

Size Range Of G Type Fin Tube

| Base Tube Specification | Fin Specification | |||

|---|---|---|---|---|

| Outside Diameter (mm) | Wall Thickness (mm) | Height (mm) | Thickness (mm) | Pitch (mm) |

| 15.88-50.8 | 1.0-3.0 | 6.35-25.4 | 0.4 | 2.1-6.0 |

| Material | Material | Length | ||

| SS, CS, Alloy Steel, Copper | CS, Aluminum, Copper | ≤ 15m | ||

Classification of Finned tubes based on process and fin shape

| Tube Outside Diameter | Fin Thickness | Fin Height | Fins per Pitch |

|---|---|---|---|

| 5/8 | .015 / .016 / .020 | 3/8, 1/2 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8, 1/2 | ||

| 1 | 5/8, 1/2 | ||

| 1 1/4 | 5/8, 1/2 | ||

| 1 1/2 | 5/8, 1/2 |

Finned tubes generally use air to cool or heat fluids such as water

Finned tubes significantly increase the surface area of the tube, enabling more effective heat transfer with air. Using air for heating or cooling is advantageous because it is readily available, economical, and eliminates the need for complex heating equipment or labor-intensive operations.

High fin tubes Vs Low fin tubes

| Features | High Fin Tubes | Low Fin Tubes |

|---|---|---|

| Fin Density | Higher fin density | Lower fin density |

| Heat Transfer Efficiency | Superior due to higher fin density | Lower compared to high fin tubes |

| Surface Area-to-Volume Ratio | Higher due to dense finning | Lower due to less dense finning |

| Maintenance and Cleaning | Requires more frequent maintenance | Less maintenance needed |

| Cost Considerations | More expensive due to complex manufacturing | More cost-effective |

What can Cause Leakages in Low Fin Tubes?

- Scale buildup: This narrows the inner diameter, leading to pressure buildup and eventual leakage.

- Thermal shock: Rapid temperature changes can cause cracks or ruptures in the tube.

- Improper installation: Proper installation and regular maintenance help prevent leaks.

- Tube corrosion: Corrosion increases the risk of leakage.

What Affects the Heat Transfer in a Low Fin Tube?

Several factors influence the effectiveness and efficiency of heat transfer in low fin tubes:

- Fluid properties

- Fin arrangement

- Number of fins

- Dimensions of the fins

- Surface finish

1. Adjustable height: The L Banner stand is designed with an adjustable height feature, allowing you to customize the height according to your preference and needs.

2. Lightweight and portable: The L banner stand is lightweight and easy to transport, making it an ideal choice for trade shows, exhibitions, and other events.

3. Easy to set up: The L banner stand is easy to set up and requires no tools or special skills. You can set it up in minutes without any hassle.

4. Durable construction: The L banner stand is made of high-quality materials that are durable and long-lasting. It can withstand frequent use and is resistant to wear and tear.

5. Versatile: The L banner stand is versatile and can be used for a variety of applications, including trade shows, exhibitions, conferences, and other events.

6. Customizable: The L banner stand is customizable, allowing you to add your own graphics, logos, and other branding elements to promote your business or organization.

7. Affordable: The L banner stand is an affordable option for businesses and organizations looking to promote their brand at trade shows and other events.

Adjustable L Banner,L Banner Stand,L Adjustable Banner,Retractable Adjustable Outdoor Banner Stand

SUZHOU JH DISPLAY&EXHIBITION EQUIPMENT CO.,LTD , https://www.jh-displaystand.com