Site Bite: Replacing the coil in a Liebert® condensing unit

Site Bite: Replacing the Coil in a Liebert® Condensing Unit

Join Chris Wright, a Chicago-area Account Manager, as he heads out to P&W Foundry for an urgent job. The situation was anything but typical — the condensing unit was running at dangerously high temperatures, and time was of the essence.

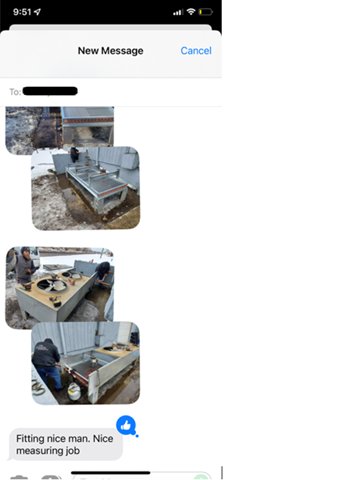

The site was located in Plano, IL, and the unit was responsible for cooling a production floor that manufactured critical parts for the U.S. Navy. A breakdown would have caused major delays, so we knew we had to act fast. We arrived on the same day we received the call and immediately started measuring for a replacement coil.

Since the rest of the system wasn’t being replaced, it was crucial to match the original coil exactly — from the number of feeds, to the fins per inch, and the piping connections. This ensured a direct replacement with no performance loss. The coil itself was large, but it was easily accessible, making the measurement process straightforward.

There were several non-standard features on this coil, like copper connections that extended from the bottom of the headers. We needed to replicate this design precisely for a smooth field installation. The flanges were also built differently, requiring an extra bend on each plate to provide better stability on the four pillars the coil rested on.

With detailed sketches and thorough notes, we made sure every custom detail was covered. The customer had a tight 5-day production schedule, and we delivered right on time. They were thrilled with how easy the installation was and how well the new coil performed once it was in place.

This job reminded us just how important precision and attention to detail are when it comes to industrial HVAC systems. Every component must be exact — especially when it's supporting mission-critical operations. It was a great experience working with the team at P&W Foundry, and we're proud to have helped them get back up and running quickly.

Written by: Chris Wright

Nationwide Coils Account Manager, Chicago

Wine Decanter,Wine Glass Decanter,Clear Glass Decanter,Glass Decanter

Xuzhou Bolite Import & Export Trading Co.,Ltd. , https://www.xzbltglass.com