Flexible Mounting Options for Compact Stepper Motor Drivers

Certainly! Here's the rewritten content in English:

---

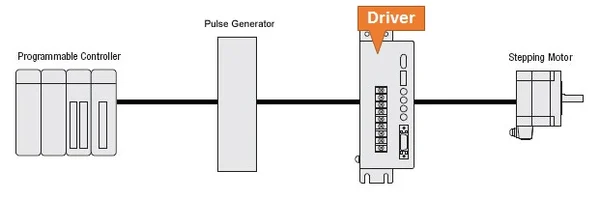

A stepper motor requires a driver to function effectively. The driver interprets signals from the controller and manages the operation of the motor. It ensures the correct current is sent through the motor phases, regulating torque and step precision. As machines become increasingly compact, finding space for the driver can be a challenge.

**Standard Stepper Motor System Configuration**

Oriental Motor recognizes this trend and has developed stepper motor drivers with versatile mounting options to suit diverse machine designs.

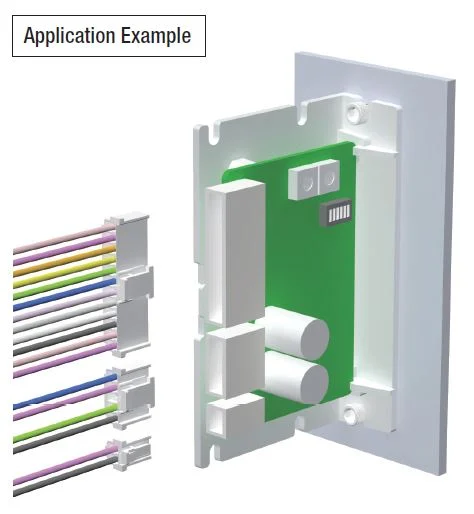

**Challenge 1: Mount a Driver Vertically with Horizontal Connections**

**Solution: Use a Right Angle Driver with Mounting Plate**

This type of driver has connectors facing outward, parallel to the circuit board. Matching connectors are included. A right-angle driver with a mounting plate can also be paired with a driver cover and a DIN rail mounting bracket.

*Right Angle Driver with Mounting Plate*

**Accessories**

- **Driver Cover**

- **DIN Rail Mounting Bracket**

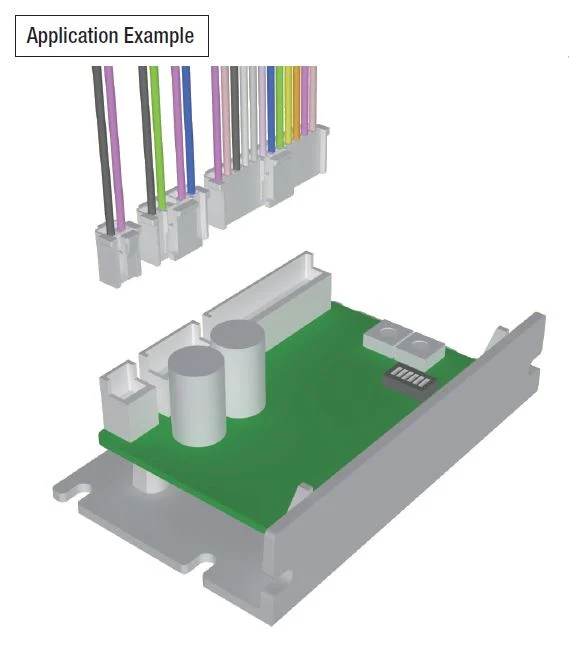

**Challenge 2: Mount a Driver Horizontally with Vertical Connections**

**Solution: Use a Driver with Mounting Plate**

This driver has its connector facing upward, perpendicular to the circuit board. Matching connectors are provided.

*Driver with Mounting Plate*

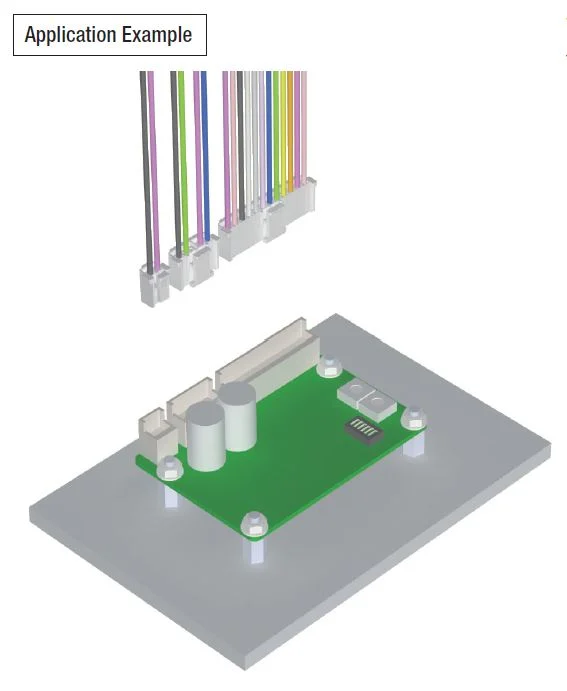

**Challenge 3: Mount a Driver Directly on a Metal Plate**

**Solution: Use a Driver without Mounting Plate**

This driver has connectors facing upward, perpendicular to the circuit board. Design enhancements like high-efficiency FETs mean a heat sink isn’t necessary. Matching connectors are included.

*Driver without Mounting Plate*

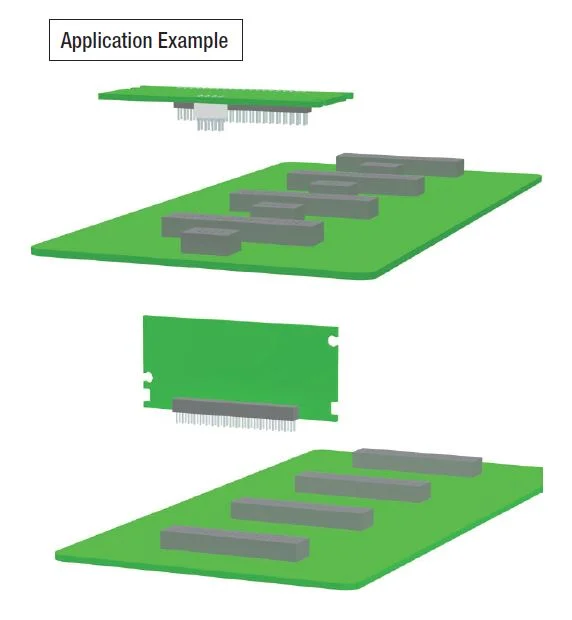

**Challenge 4: Mount a Driver Directly to a PCB**

**Solution: Use S-Type Drivers**

These drivers are ideal for engineers designing custom solutions and can be installed directly onto a PCB via pin socket or direct solder. Both vertical and horizontal S-types are available with either I/O only or SPI bus communication.

*S-Type Driver (Available with SPI Bus)*

To learn more about how our CVD drivers can enhance stepper motor performance, explore our offerings for 2-phase or 5-phase stepper motors. While 2-phase is more common, 5-phase models offer reduced vibration and noise.

**CVD Drivers for 2-Phase Stepper Motors**

**CVD Drivers for 5-Phase Stepper Motors**

For a quick overview of the CVD driver’s capabilities, watch this short video:

- Smooth Drive full-time advanced microstepping

- High efficiency FETs

- Digital current setting

- Vibration demonstration at resonant frequencies

- Mounting types

If you need assistance choosing the right driver model for your stepper motor, feel free to reach out.

*Contact Us*

---

I hope this meets your requirements! Let me know if further adjustments are needed.

Jet Mill,Energy Saving Jet Mill,Glass Beads Classifying Jet Mill,Pesticide Industry Specific Jet Mill

Mianyang Liuneng Powder Equipment Co., Ltd , https://www.lnpepowder.com