Dedicated Robot Controller and Programming Software Makes Robotics Easier

Â

With the growing need for automation due to labor shortages and the increasing demand for error-free efficiency in manufacturing, more and more companies are seeking ways to incorporate robotics into their operations. However, many businesses struggle to implement robotics automation because they lack the necessary funds or technical expertise. While outsourcing the purchase and programming of a robot may seem like an easy solution, designing and programming your own robot can be simpler than you think.

Â

An Easier Way to Build and Program Robots

Â

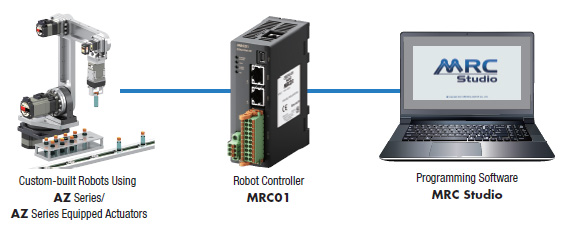

Oriental Motor has introduced a new robot controller and programming software designed to make multi-axis robotics applications more cost-effective, straightforward to build, and easier to program using off-the-shelf, standard products. These tools aim to eliminate common barriers to entry for building robots in-house.

Â

Â

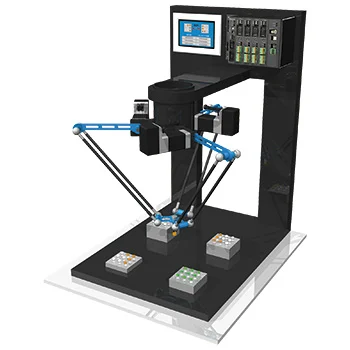

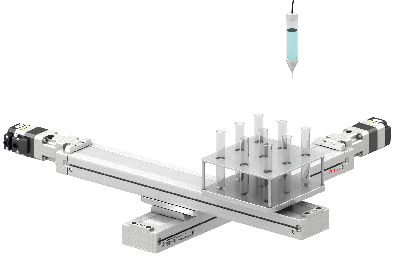

The MRC01 robot controller and MRC Studio programming software are designed to work with a variety of robot types and end-effectors:

Â

| Vertically Articulated Robots | Horizontally Articulated (SCARA) Robots | Palletizer/Parallel Link Robots | Perpendicular / Cartesian / Gantry Robots |

| 3 links | 2 or 3 lnks | 1 or 2 links | 2 or 3 axes |

|

|

|

|

Currently, the MRC01 and MRC Studio are available for vertically articulated robots, horizontally articulated (SCARA) robots, and palletizer/parallel link/delta robots. For support on 2~3 axis perpendicular/cartesian/gantry systems, please contact our tech support team.

Â

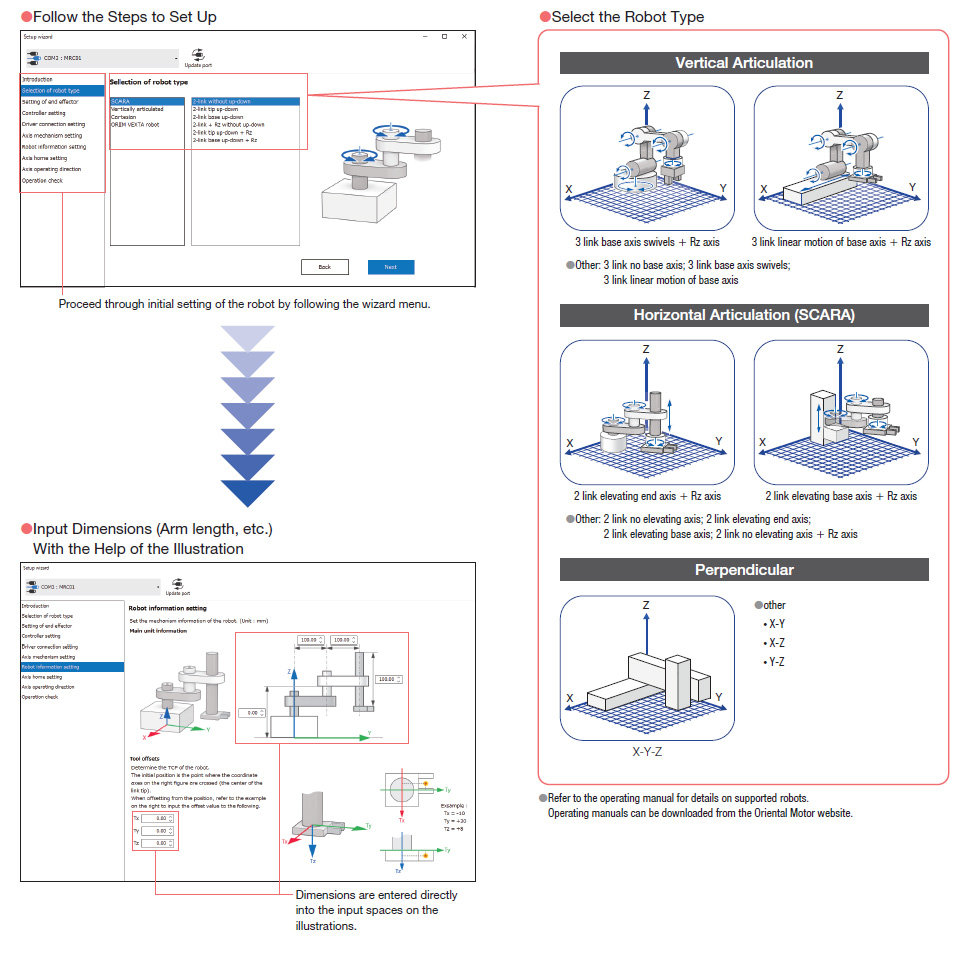

STEP 1  Easy Setup with Step by Step Guidance

Initial settings are made using a wizard to select the robot type and input mechanism information.

By following the guidance instructions while looking at the illustrations, even absolute beginners can quickly set up a robot's initial settings.

Â

Â

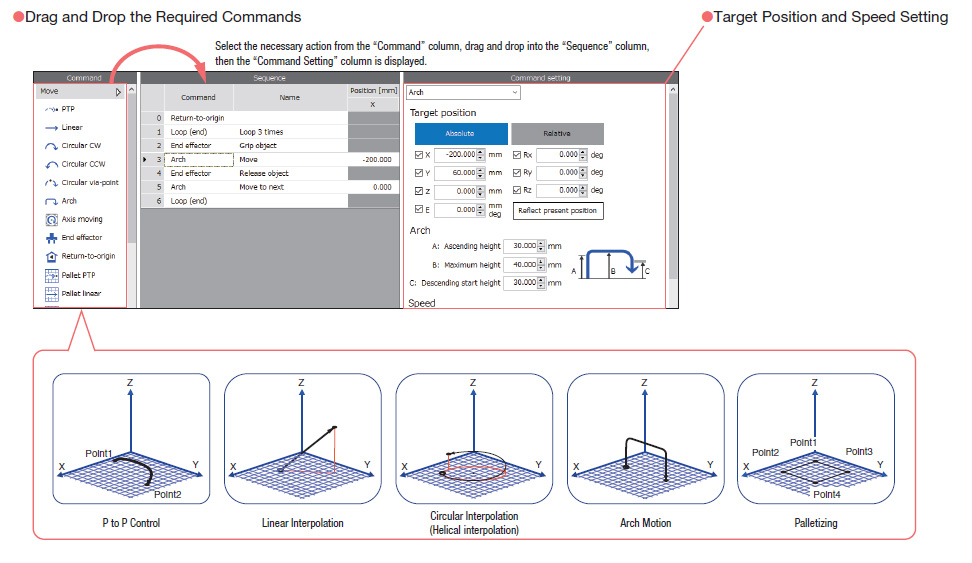

STEP 2  Goodbye to Ladder Logic! Select Items to Program Operation

Program creation uses a simple command selection format. Programs can be created intuitively, without requiring specialized knowledge such as ladder diagrams. The system supports P to P operation, linear interpolation operation, circular interpolation operation, arch motion and others.

Â

Â

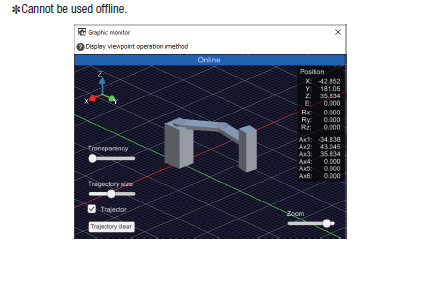

STEP 3 Check Operation with an Online 3D Simulator

The robot’s operation program can be checked using a 3D simulator. The program can be checked easily before the actual robot is activated.

Â

Â

| TIP | When setting the home position for all axes, remove holding torque from all motors by turning on the FREE input on their drivers, then manually adjust to the home position. All AlphaStep AZ Series motors and actuators use a built-in mechanical absolute encoder, so absolute position coordinates are tracked even with the power off. |

Â

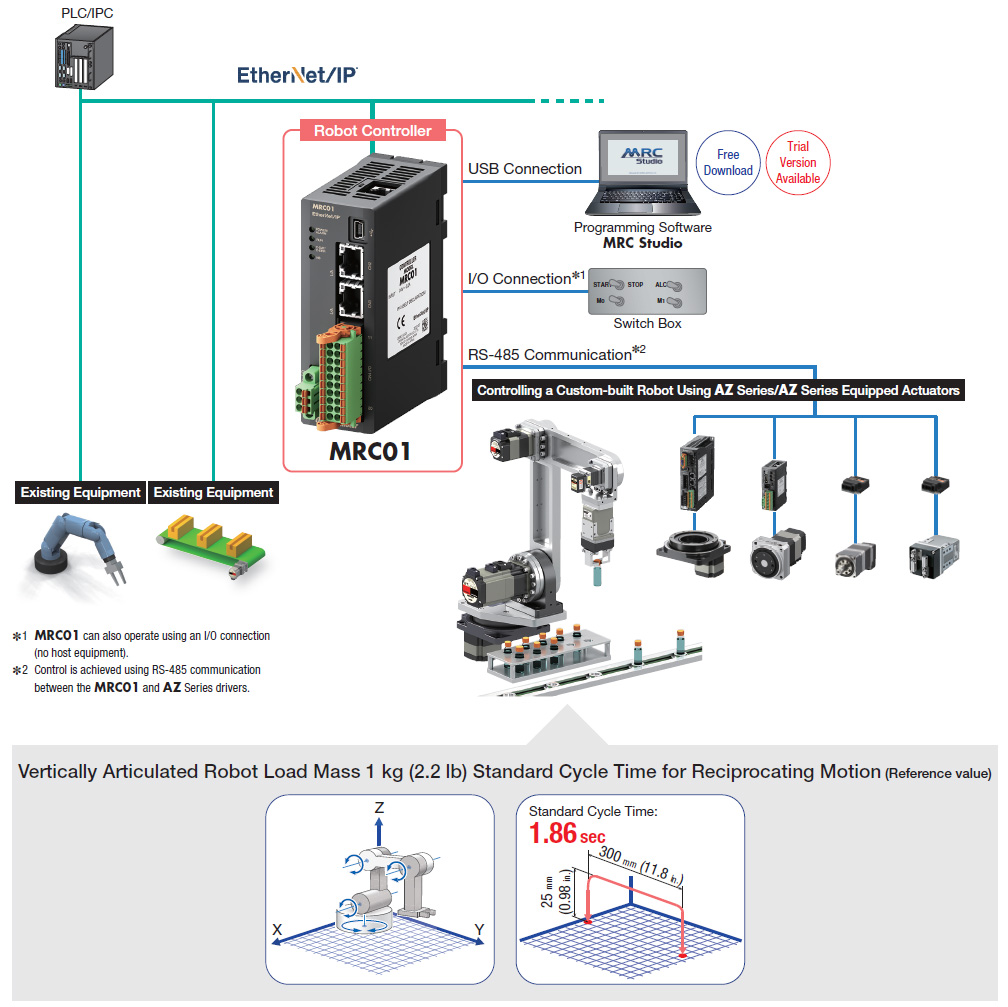

The MRC01 robot controller communicates to the PLC/IPC via EtherNet/IP and controls motors and linear/rotary actuators from the AlphaStep AZ Series family through dedicated drivers via Modbus RTU. The MRC01 is compatible with AZ Series built-in controller type drivers, such as the AZD-AD (AC input RS-485 driver with built-in controller), AZD-KD (DC input RS-485 driver with built-in controller), and AZD-KR2D (mini DC input RS-485 driver with built-in controller).

The MRC01 robot controller also comes with dedicated robotic functions, such as palletizing command, "passing point designation system" (for circular interpolation operation), and JOG/inching operation in a tool coordinate system.

Use the AlphaStep AZ Series family of products to support your in-house design for improved performance and ease of use.

- Easily introduce custom-built robots to existing systems

- Direct control via EtherNet/IPâ„¢

- Easy setup even for beginners (no ladder logic)

- Experience the "MRC Studio" programming software (trial version) before purchase

- Use with AZ Series drivers: built-in controller type (AC/DC) or mini driver RS-485 communication type (24/48 VDC)

Â

Â

The MRC01 robot controller is designed for users who would like an easier way to control their in-house-built robots and want to communicate to a PLC or IPC via EtherNet/IP. The MRC Studio programming software introduces a new and simple way to program multi-axis motion and can be downloaded for free. Typically, the software only works with a combination of a motor/actuator and a driver that will have to be purchased prior. If you would like to try it before you buy it, a trial version of the MRC Studio programming software is available for download.

Â

Â

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '76574a7f-a963-4255-bcf5-1cb7ab5d3fc2', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '76574a7f-a963-4255-bcf5-1cb7ab5d3fc2', {"useNewLoader":"true","region":"na1"});

Â

Summary

The MRC01 robot controller and MRC Studio programming software present a new and simple way to program and control multi-axis robotics without ladder logic knowledge. For robotics applications that do not require highly aggressive motion profiles, the MRC01 robot controller and the AlphaStep AZ Series family of modular type motors, linear/rotary actuators, and dedicated smart drivers can make in-house robotics easier and faster to build without compromising quality and reliability.

Contact our team today for product demos!

Â

BONUS  What else might you want to know?

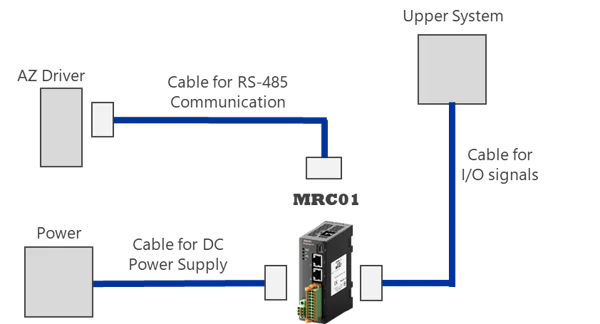

Here's a simple system configuration for the MRC01 robot controller.

Â

To help you set up quickly, we offer these pre-made cables as accessories.

Â

|

Cable Type |

Model Name |

Length (m) |

|

RS-485 Communication Cable (For connecting FLEX drivers) |

CCâ–¡â–¡â–¡-RS4

|

0.1, 0.25 |

|

RS-485 Communication Cable (For connecting mini Driver) |

CCâ–¡â–¡FLT6

|

2, 5 |

|

Cable for I/O Signals General-purpose type |

CCâ–¡â–¡D0â–¡â–¡â–¡B-1

|

0.5 ~ 2 |

|

Cable for DC Power Supply |

CC02Dâ–¡â–¡â–¡-3

|

0.5~5 |

Â

Here are the specifications of the MRC01 robot controller.

Â

The AlphaStep AZ Series family supports modular and cost-effective robot builds.

Â

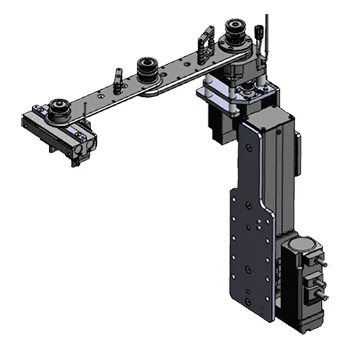

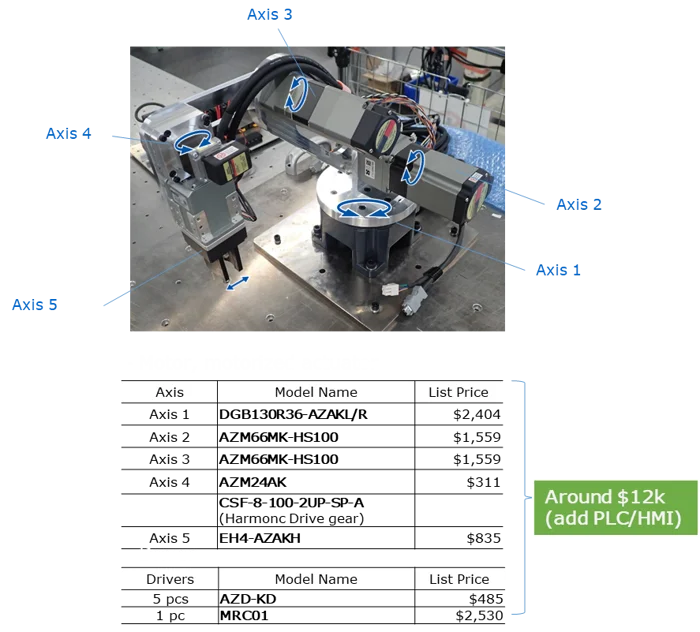

The picture below shows an in-house made robot made by our own factory engineers for a parts transfer operation. With modular products from the AlphaStep AZ Series family (motors, actuators, and drivers), we were able to build and program a 5-axis vertically articulated robot faster and more cost-effectively while similar robots in the market cost much more. To complete the system, all you have to do is add the extra gear and a PLC/HMI that offers EtherNet/IP communication.

Â

Â

Unlock the full potential of the MRC01 robot controller with the AlphaStep AZ Series family of motors, linear/rotary actuators, and drivers! If you have any questions, please contact our knowledgeable tech support team.

Â

"Bhp Hydraulic Gear Pumps,Low Noise Gear Pumps,Hydraulic Pump,Alloy Body Gear Pump

Huaian Hy-waloil Machinery Co.,Ltd , https://www.hywaloil.com