ZGJ Mechanical Seals for Paper-making Equipment, Alumina Plants, Flue Gas Desulphurization, Deashing System and Slurry Pumps

Model No.: ZGJ

Type: HQ901

Balance: Balanced

Trademark: Yalan

Transport Package: Wooden Case

Specification: Inner Diameter: 20 mm to 220 mm

Origin: China

HS Code: 8484200090

ZGJ Mechanical Seals are specifically designed for use in paper-making equipment, alumina plants, flue gas desulphurization (FGD) systems, deashing systems, and pressure screens used in paper pulp agitation. These seals are ideal for environments where high durability and reliability are required due to the presence of abrasive and corrosive media.

**Structural Features:**

The ZGJ series features a single-end mechanical seal with multiple springs, a spring protector, and a balanced design. It includes an external seal flush system that enhances sealing performance and extends service life. The seal is cartridge-style, making installation quick and straightforward without the need to disassemble the seal cavity. The springs are isolated from the process medium, preventing jamming caused by high viscosity or crystallization. This ensures consistent flexibility of the compensation ring, contributing to long-term performance. Both the stationary and rotating rings are equipped with L-shaped pads, offering greater adaptability to temperature fluctuations.

**Standards:**

Currently, no specific standards are listed, but the product meets industry requirements for similar applications.

**Application Areas:**

These seals are commonly used in paper mills, alumina processing units, flue gas desulphurization systems, power plant deashing systems, and slurry pumps. They are especially suitable for handling media containing solid particles such as paper pulp, coal ash, slag, and other suspensions.

**Operating Parameters:**

- Pressure: 0 – 2.4 MPa

- Temperature: -40°C – 180°C

- Linear Speed: ≤15 m/s

- Cooling Water Pressure: ≤0.1 MPa

- Solid Content: ≤30%

**Media Type:**

Designed for use with paper pulp, coal cinder, slag, ash, and other fluids containing solid particles.

**Customization Options:**

Material modifications can be made to accommodate different operating conditions. Please contact us with your specific requirements for tailored solutions.

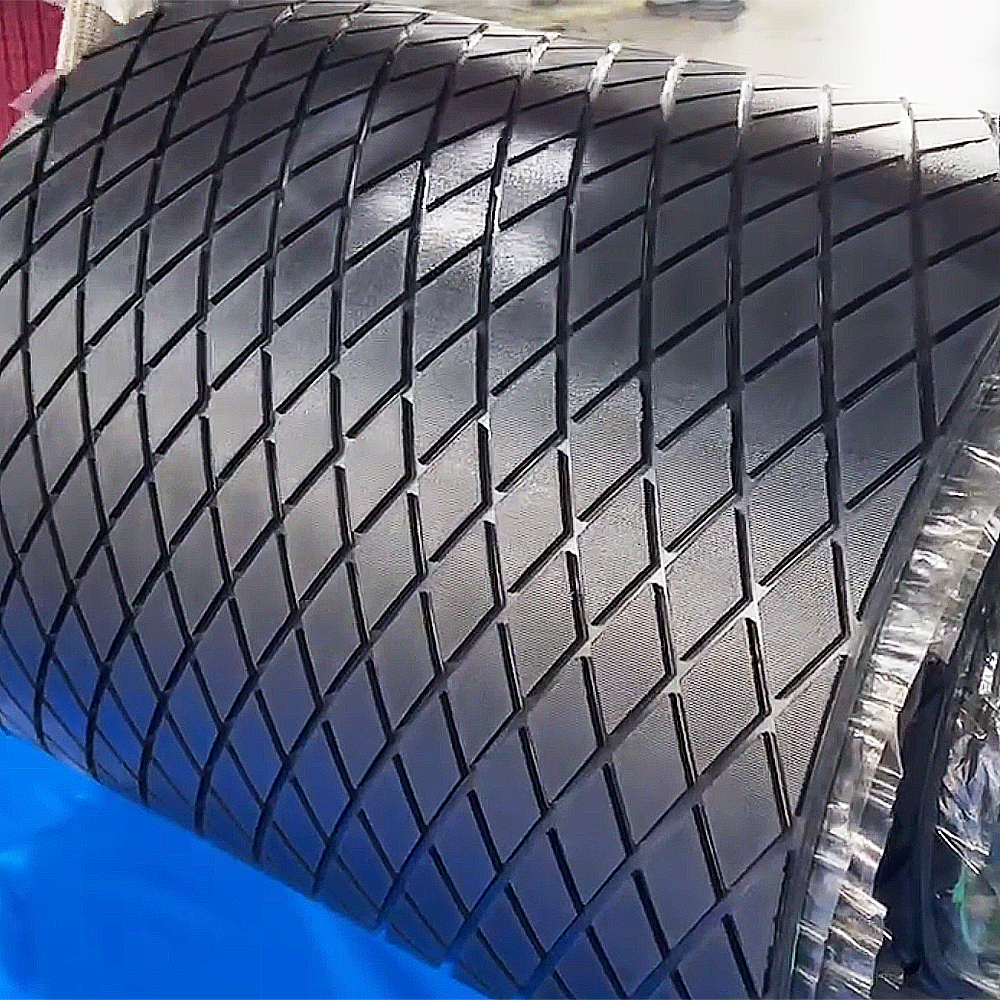

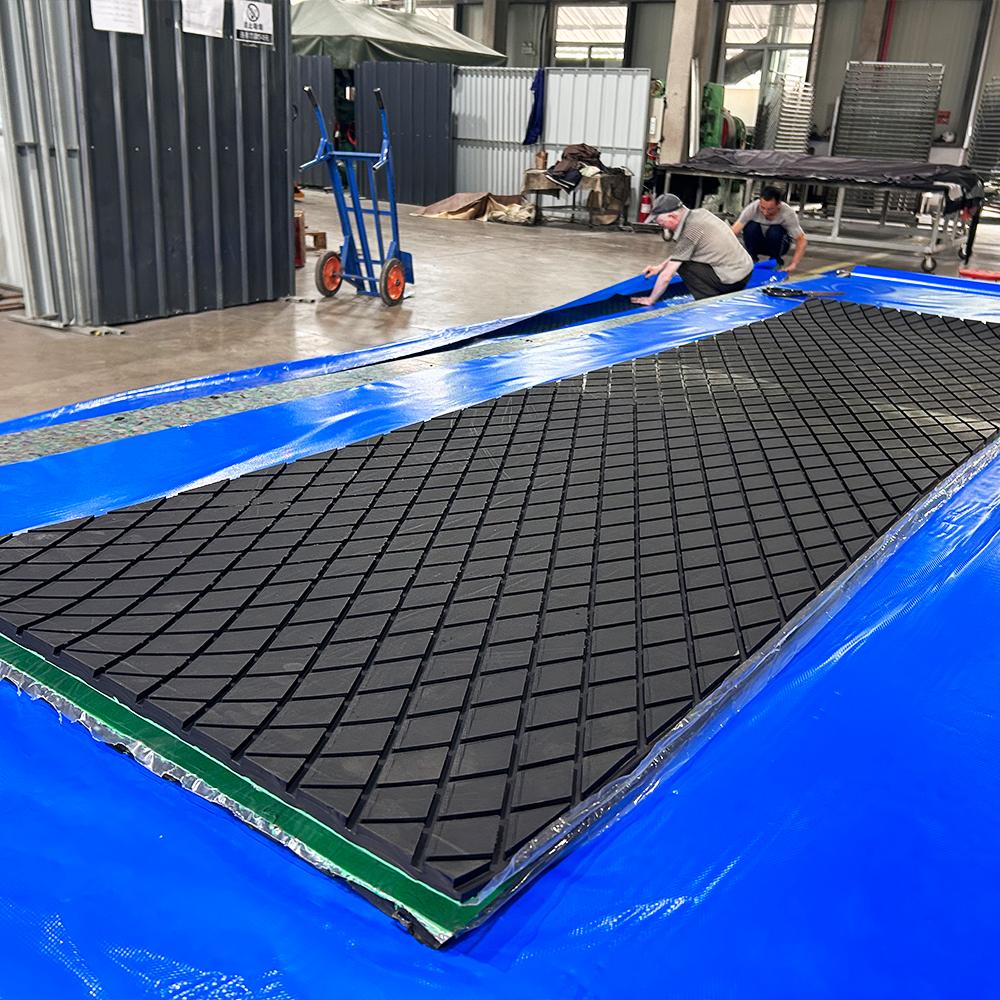

Roller Covered Rhombic Rubber Sheet

Roller cover rubber free sanding wear resistant rhombic rubber sheet is also known as “rhombic roller cover rubber” is a kind of pre-slotted rubber sheet, suitable for active wheel cover rubber.

The rubber sheet has molded regular rhombic blocks, which protects the surface of the drum from adhering to the transport material and avoids deflection.The regular rhombic blocks can improve the sliding friction coefficient of the rubber sheet, which is also the characteristic of the rhombic rubber sheet, and the high sliding friction coefficient can reduce the slippage between the roller and the conveyor belt.

Still struggling with frequent roller changes and production interruptions? Choosing our roller covers with rhombic rubber sheets will completely change your operation! The unique rhombic pattern with carefully designed grooves provides superior grip and ensures smooth material transfer in even the harshest environments. Whether it's an abrasive mine, a busy harbour or a hectic factory, our rhombic rubber sheeting resists wear, tear and corrosion in any environment. Say goodbye to downtime and hello to soaring productivity.

rhombic rubber sheet,pulley lagging rubber sheet,rubber pulley lagging,Roller covered rhombic rubber sheet,rhombic rubber plate

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com