ATTI Mode: A Guide

ATTI Mode: A Comprehensive Guide

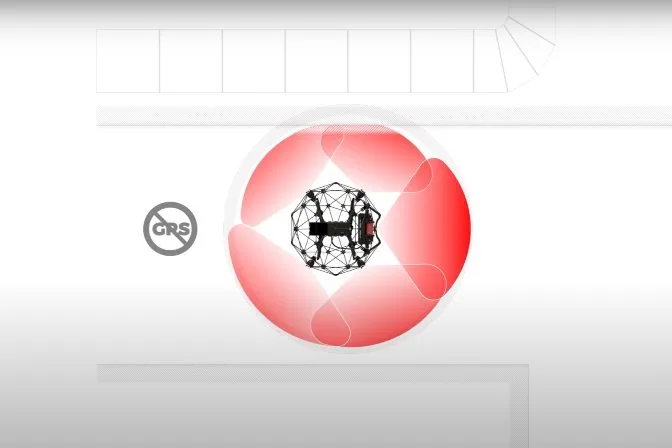

ATTI mode, short for Attitude Mode, is the most hands-on way to fly a drone. It gives the pilot complete control over the aircraft without relying on GPS or visual positioning systems.

As drone technology continues to evolve, there has been a strong push towards automation and smart flight features that make flying easier and safer. However, ATTI mode still plays an important role in specific scenarios where traditional navigation systems are not reliable.

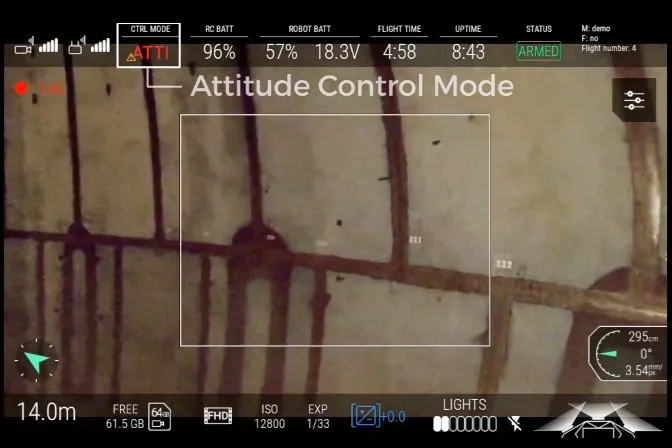

One of the key applications for ATTI mode is in indoor environments, where GPS signals can be weak or completely unavailable. In these situations, pilots must rely on their own skills and instincts to maneuver the drone safely.

In ATTI mode, the drone's optical sensors are disabled, and the pilot takes full responsibility for controlling the drone’s attitude. This mode is often used when the drone starts behaving unpredictably due to environmental factors like poor lighting or reflective surfaces.

No GPS zone

What Is ATTI Mode?

ATTI mode is a manual flight setting that disables all intelligent assistance from GPS and optical sensors. In this mode, the drone doesn't automatically correct its position or altitude, making it more challenging to fly but also more flexible in certain environments.

Most modern drones operate in GPS or OPTI mode, which use satellite and visual data to stabilize the flight. However, in ATTI mode, the drone becomes more sensitive to wind and other external forces. Pilots need to be highly skilled to maintain control and avoid crashes.

[Related read: What Is a GPS-Denied Drone?]

When to Use ATTI Mode

While ATTI mode was once a common feature in older drones, it's now more relevant in specialized applications. It's especially useful for indoor flights, where GPS signals are unreliable or non-existent.

Indoor inspections in places like mines, sewers, and industrial facilities often require ATTI mode because GPS can’t function underground or in enclosed spaces. These environments pose unique challenges, and ATTI allows pilots to navigate with greater precision.

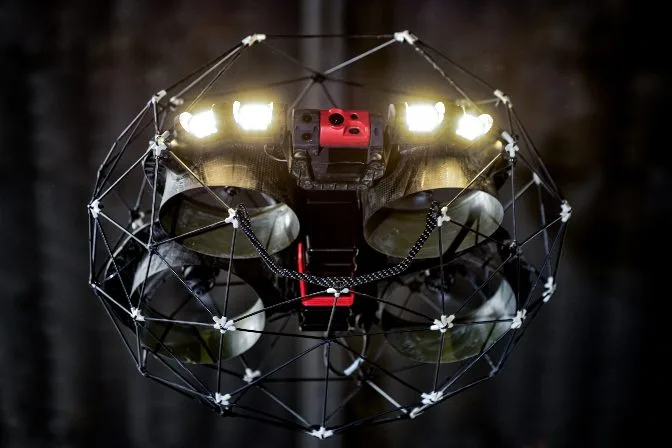

The mining industry, for example, has adopted ATTI-enabled drones for safety and efficiency. Drones like the Elios 3 are specifically designed to operate in GPS-denied environments, making them ideal for hazardous and hard-to-reach areas.

[Related read: Why We Made The Elios 3]

The Elios 3

The Elios 3

Common Use Cases for ATTI Mode

ATTI mode is particularly useful in situations where GPS signals are weak or absent. Here are some common scenarios:

- Indoor inspections: Used to inspect boilers, tanks, sewers, and other enclosed spaces.

- Bridge and building inspections: Large metal structures and concrete walls can interfere with GPS signals.

- Critical infrastructure: Sensitive areas like military bases may restrict GPS usage for security reasons.

The Elios 3 is one of the few drones built for extreme conditions, using ATTI mode to ensure safe and accurate operations in GPS-denied zones.

How Does ATTI Work?

In ATTI mode, the drone relies solely on its barometer to estimate altitude. While this helps keep the drone level, it does not prevent drifting caused by wind or turbulence. The pilot must manually adjust the drone’s orientation at all times.

What Conditions Can Trigger ATTI Mode Automatically?

- Flying over reflective or monochrome surfaces

- Dirt or debris on vision sensors

- Flying near large metal or concrete structures

- Using high-speed flight modes that disrupt signal reception

Benefits of Flying in ATTI Mode

Although ATTI mode requires more skill, it offers several advantages:

1. Preparation for Unpredictable Situations

Signal loss, interference, and malfunctions can happen at any time. Knowing how to fly in ATTI mode helps you stay in control during emergencies and reduces dependency on automated systems.

2. Ideal for Indoor Flights

Indoor environments are full of obstacles and signal disruptions. ATTI mode allows for better control in such spaces, as it doesn't rely on GPS or visual sensors.

3. Smoother Video Footage

Some professional photographers prefer ATTI mode because it avoids the automatic corrections that can cause jittery footage. While it takes practice, it can result in cleaner, more cinematic shots.

ATTI Mode Flying Tips

Mastering ATTI mode takes time, patience, and practice. Here are some tips to get started:

1. Start Slow

If you're used to GPS mode, transitioning to ATTI can feel very different. Begin with simple maneuvers like takeoff, hover, and landing before moving on to more complex patterns.

2. Practice in Open Spaces

Always practice in a wide-open area free of people, water, and obstacles. This gives you room to recover if things go wrong.

3. Monitor Weather Conditions

Wind can have a big impact on your ability to control the drone. Start with calm weather and gradually work up to stronger winds as you gain confidence.

4. Use a Budget Drone for Training

Crashing is common when learning ATTI mode. Consider using a cheaper drone for training to avoid costly damage to your main device.

The Future of ATTI Mode

While many consumer drones are moving away from manual flight options, ATTI mode still has a place in niche industries. As more sectors adopt indoor drone technology, we can expect to see more specialized drones like the Elios 3 entering the market.

Whether you're a beginner or an experienced pilot, practicing ATTI mode is a valuable skill that prepares you for unexpected situations and expands your capabilities as a drone operator.

Other Drone Flight Modes

There are three other common flight modes: ASSIST, GPS, and OPTI.

What is ASSIST Mode?

ASSIST mode uses sensors to detect nearby objects and keeps the drone stable. It’s great for beginners but less effective in low-light or featureless environments.

What is GPS Mode?

GPS mode uses satellite signals to provide accurate positioning. It enables features like Return to Home and Follow Me, making it popular among everyday users.

What is OPTI Mode?

OPTI mode relies only on optical sensors for stabilization. It works well indoors with good lighting but lacks the reliability of GPS mode.

Thermoforming is a manufacturing process used to shape plastic sheets into various custom design products. It involves heating a plastic sheet until it becomes pliable, then using a mold or a vacuum to form it into the desired custom shape.

Thermoforming and vacuum forming are both processes used to shape plastic sheets into specific forms. However, there are some differences between the two techniques:

1. Process: In thermoforming, a plastic sheet is heated until it becomes pliable, and then it is pressed against a mold using pressure or a vacuum. Vacuum forming, on the other hand, relies solely on the use of a vacuum to draw the heated plastic sheet onto the mold.

2. Mold complexity: Thermoforming is typically used for more complex shapes and intricate molds, as it allows for greater detail and precision. Vacuum forming, on the other hand, is better suited for simpler shapes and molds that do not require as much detail.

3. Material thickness: Thermoforming is often used for thicker plastic sheets, typically ranging from 0.030 to 0.250 inches in thickness. Vacuum forming is more commonly used for thinner plastic sheets, typically ranging from 0.005 to 0.060 inches in thickness.

4. Production volume: Thermoforming is generally more suitable for high-volume production due to its faster cycle times and ability to handle larger sheets of plastic. Vacuum forming is better suited for low to medium volume production, as it has slower cycle times and is limited by the size of the vacuum forming machine.

5. Cost: Thermoforming typically requires more expensive equipment and molds, making it a more costly process compared to vacuum forming. Vacuum forming, on the other hand, is a more cost-effective option for smaller production runs or prototypes.

Overall, thermoforming is a more advanced and versatile process that offers greater precision and complexity, while vacuum forming is a simpler and more cost-effective option for less complex shapes and smaller production volumes.

Thermoforming is a versatile process that is widely used in industries such as packaging, automotive, aerospace, and medical. It offers advantages such as cost-effectiveness, quick turnaround times, and the ability to produce complex shapes with high precision.

Custom Thermoforming,Thermoforming Plastic Products,Thermoforming Process,ABS Thermoforming

Dongguan Yiyongli Industrial Co.,Ltd. , https://www.absthermoforming.com